-

-

Products

-

Company products

-

-

-

-

-

Copeland Scroll ZB Series Frozen Compressor

Key words:

Classification:

Product Description

features and advantages

high energy efficiency ratio

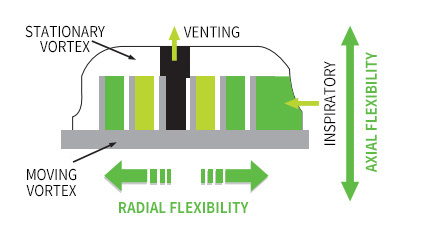

Scroll run-in instead of wear

• Better performance with increased runtime

• High volumetric efficiency

Lower noise and vibration levels

Smooth sound spectrum and soft sound quality

• Compression cavities are always symmetrically distributed

• Very low unbalance stress

• High-precision manufacturing process

• No need for vibration absorption devices

Unload Startup Technology

The compression parts are separated from each other after shutdown. The overall pressure balance inside the compressor does not require additional starting devices.

High-strength DU bearings

• Upper main bearing and drive bearing

Space Age Materials

(1) Porous permeable bronze

(2) PTFE coating

• In the absence of complete lubrication

Extend running time

• Very small coefficient of friction

Copeland Freeze Vortex Compression technology provides an outstanding solution for freezing applications.

Scroll compressors are ideal for high reliability, high energy efficiency, compact system design.

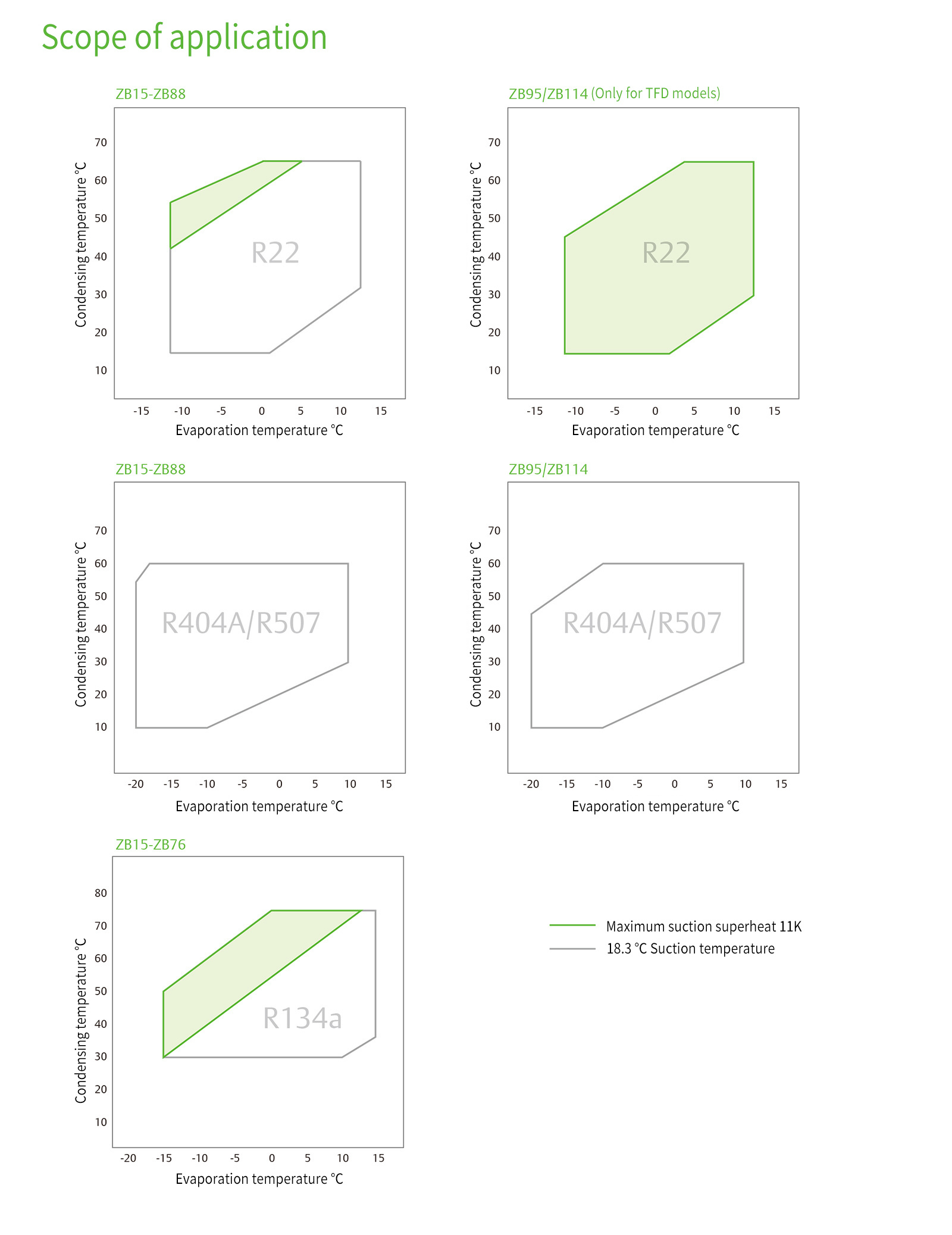

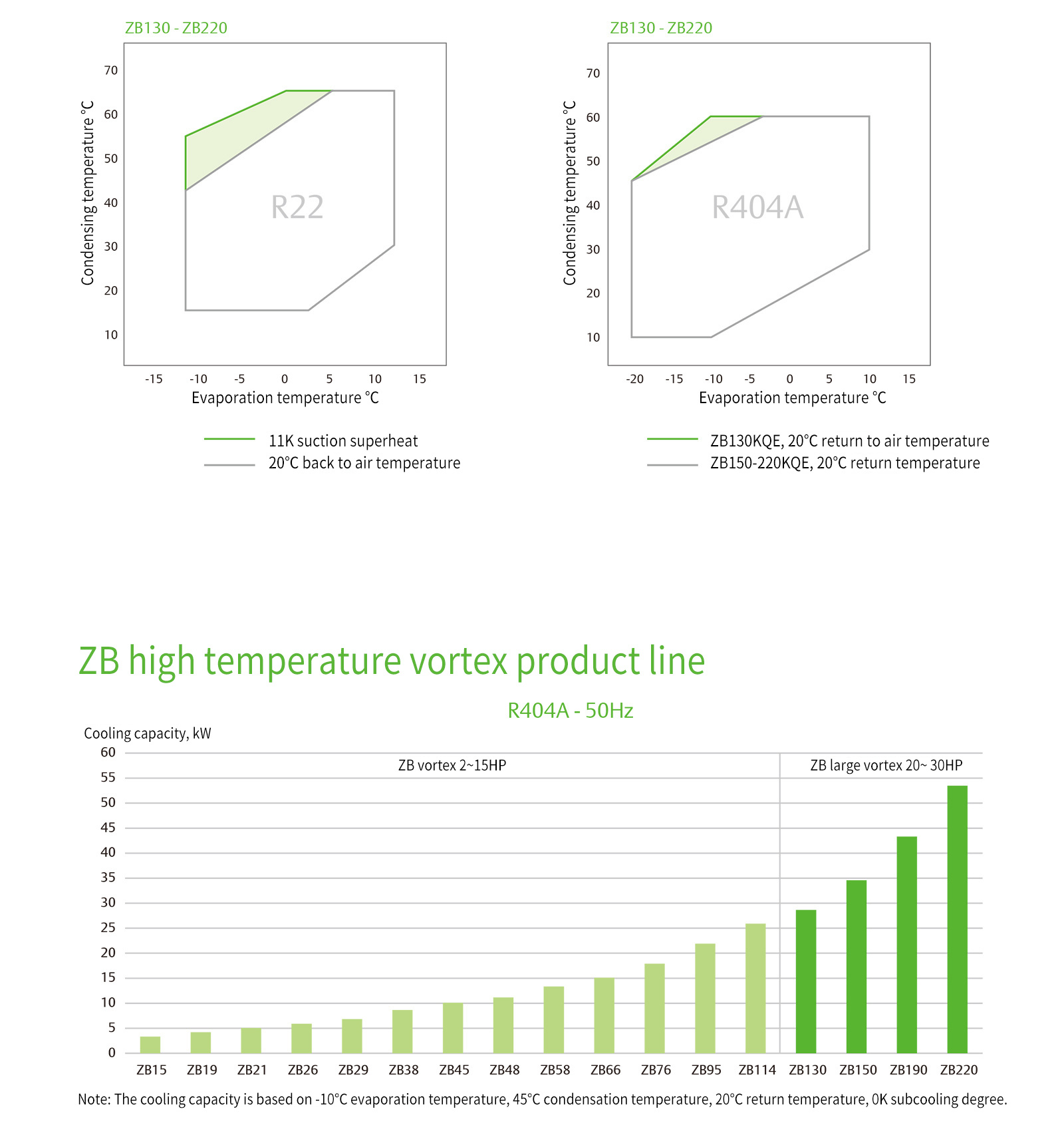

ZB series can provide the product series of 2-30HP, applicable refrigerants include R22, R404A, R134a, etc.

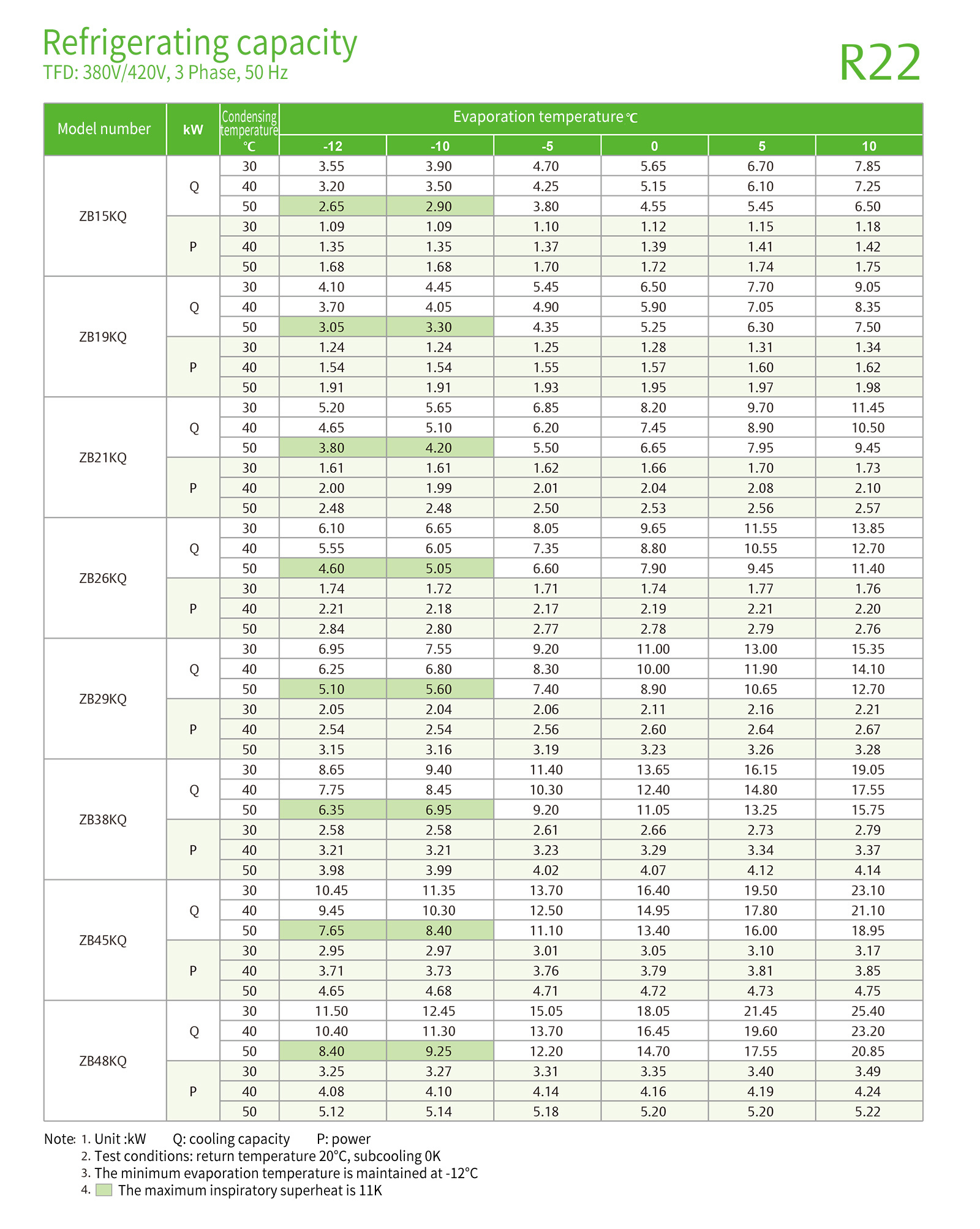

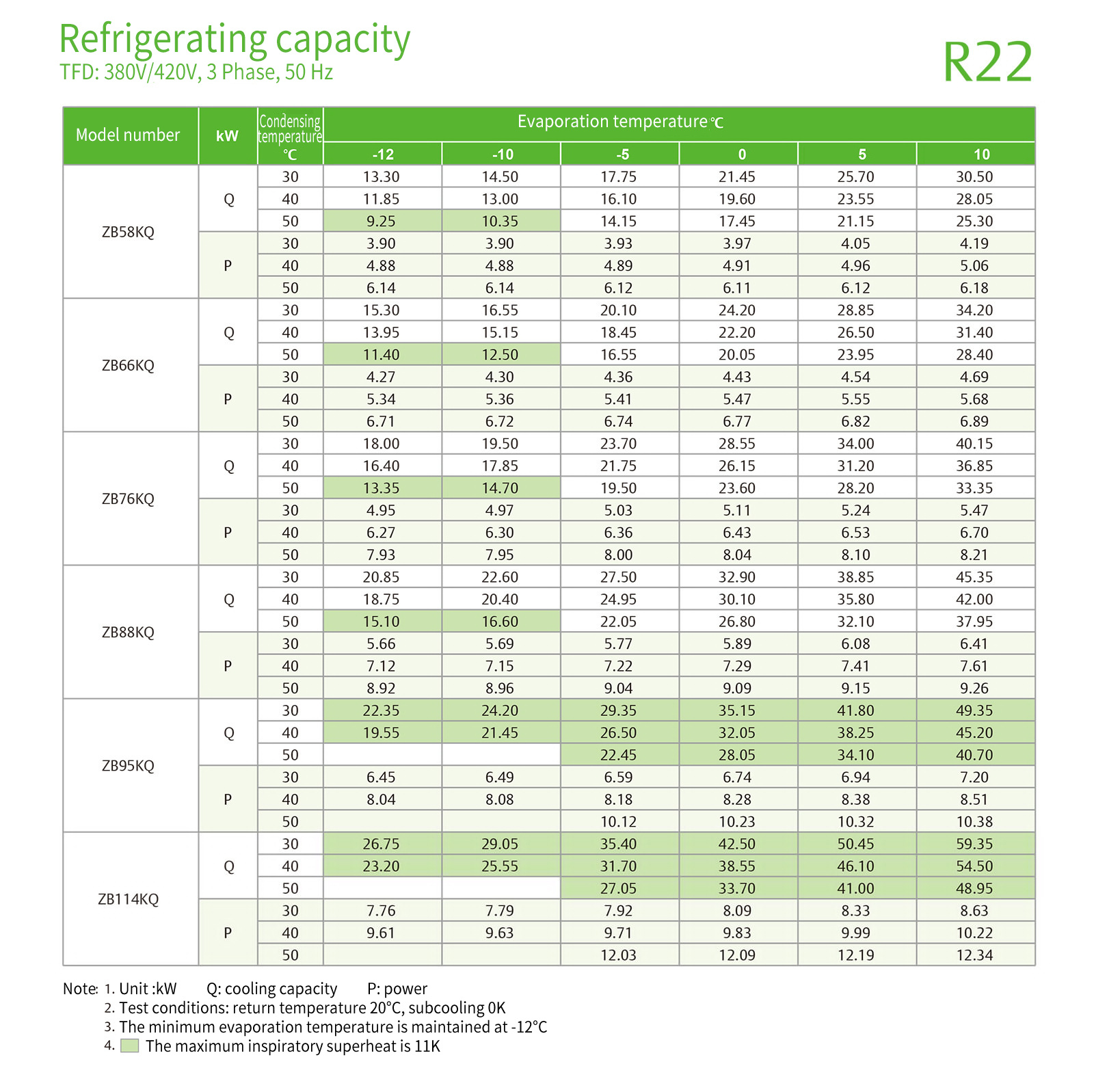

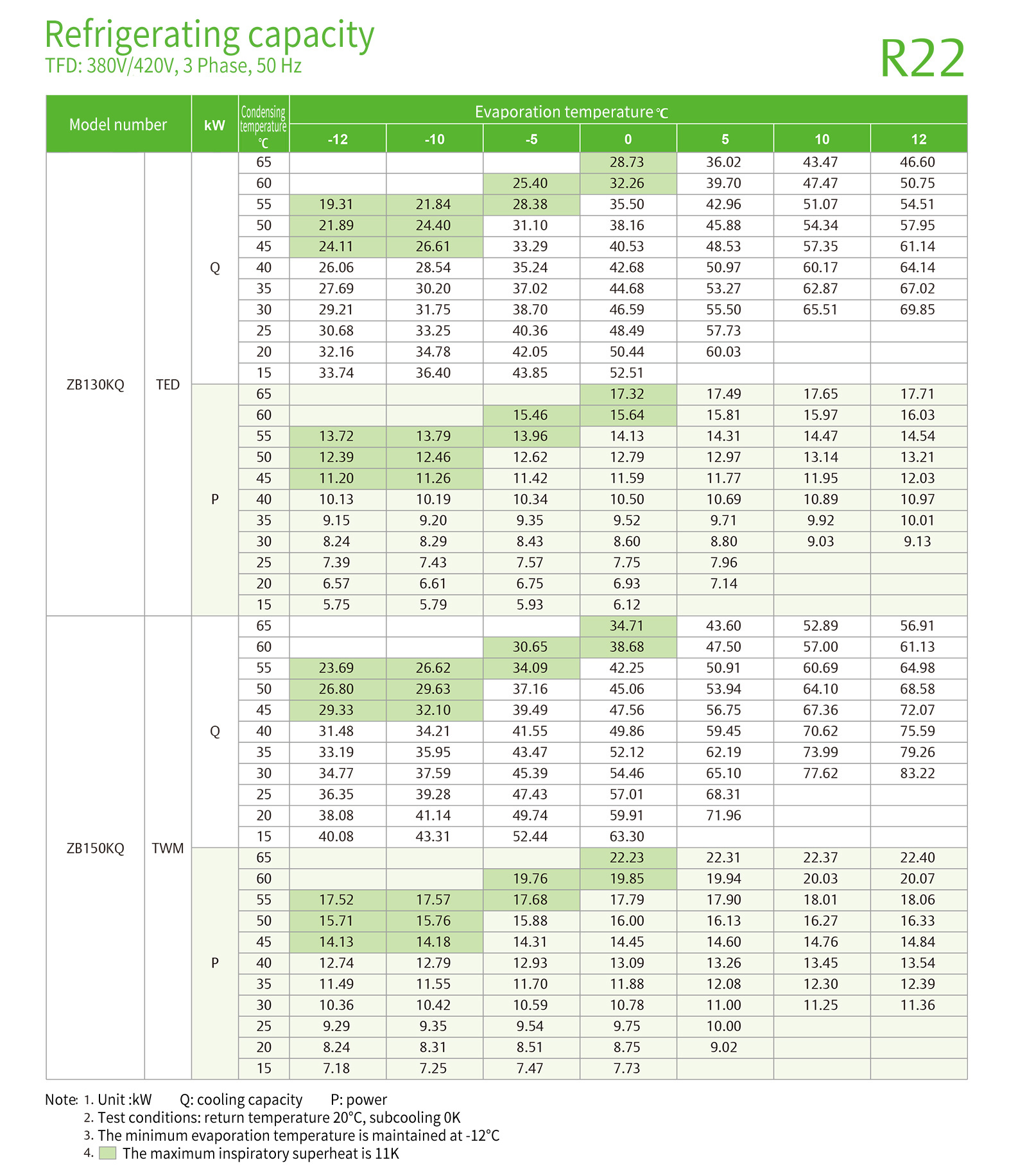

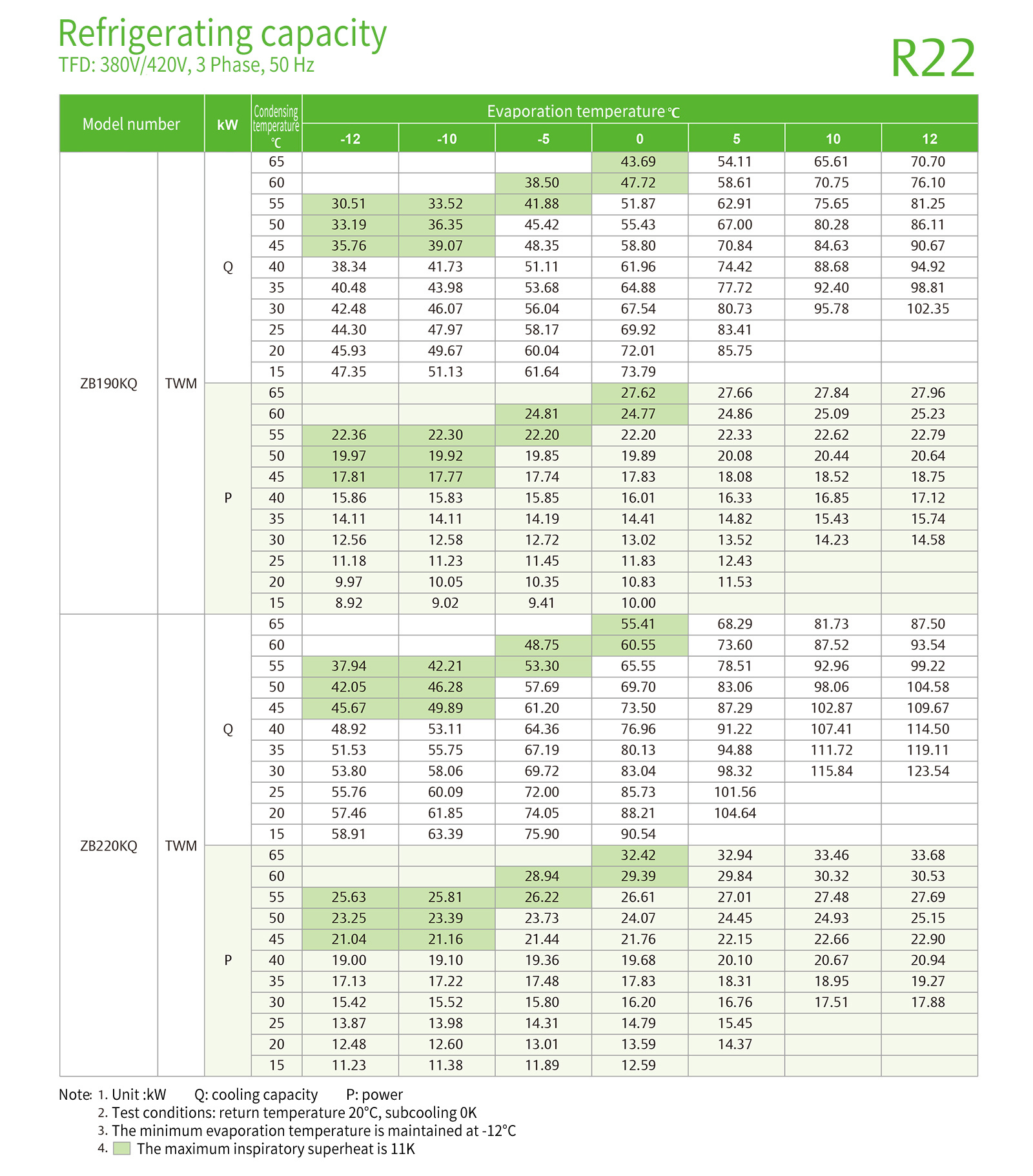

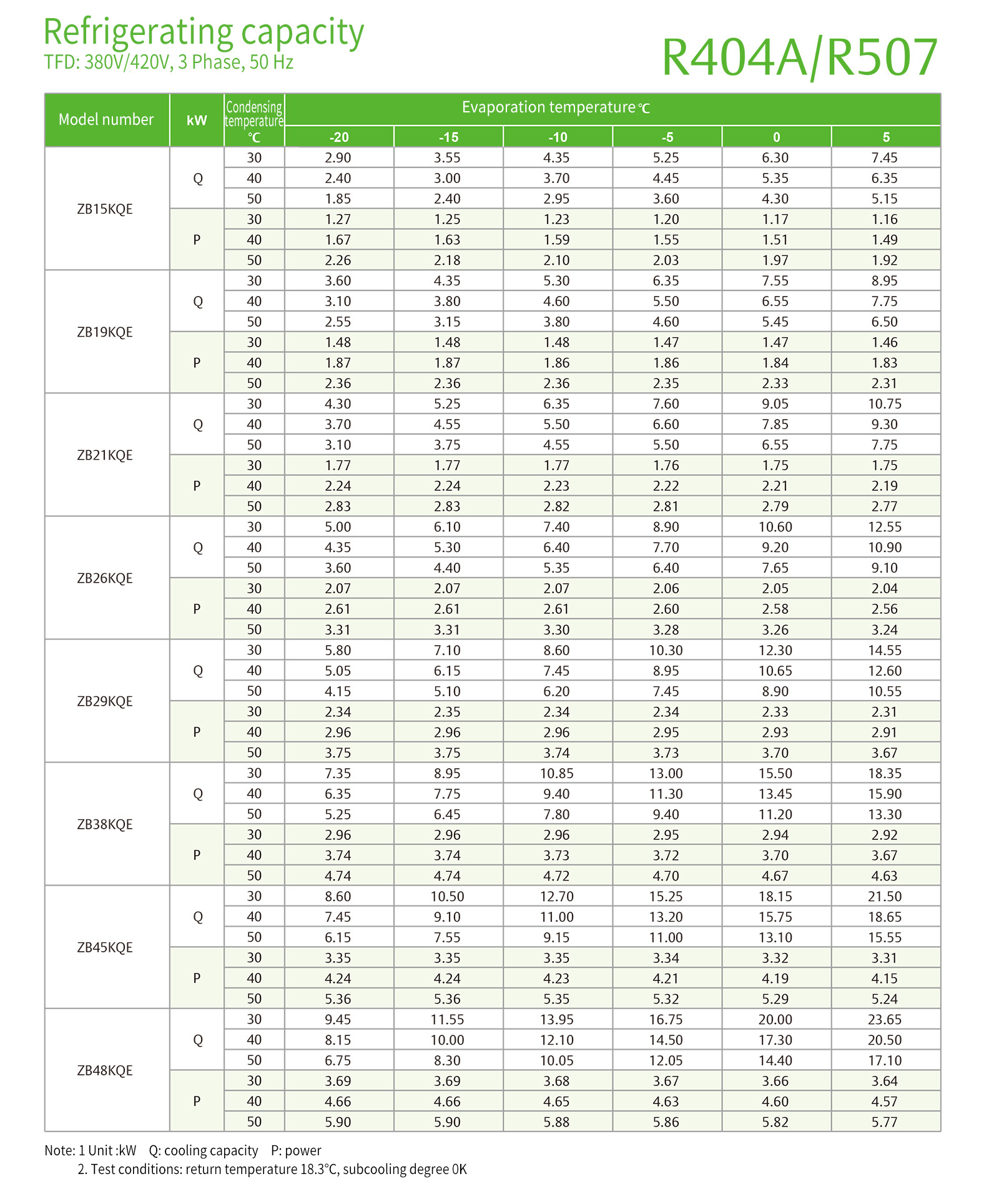

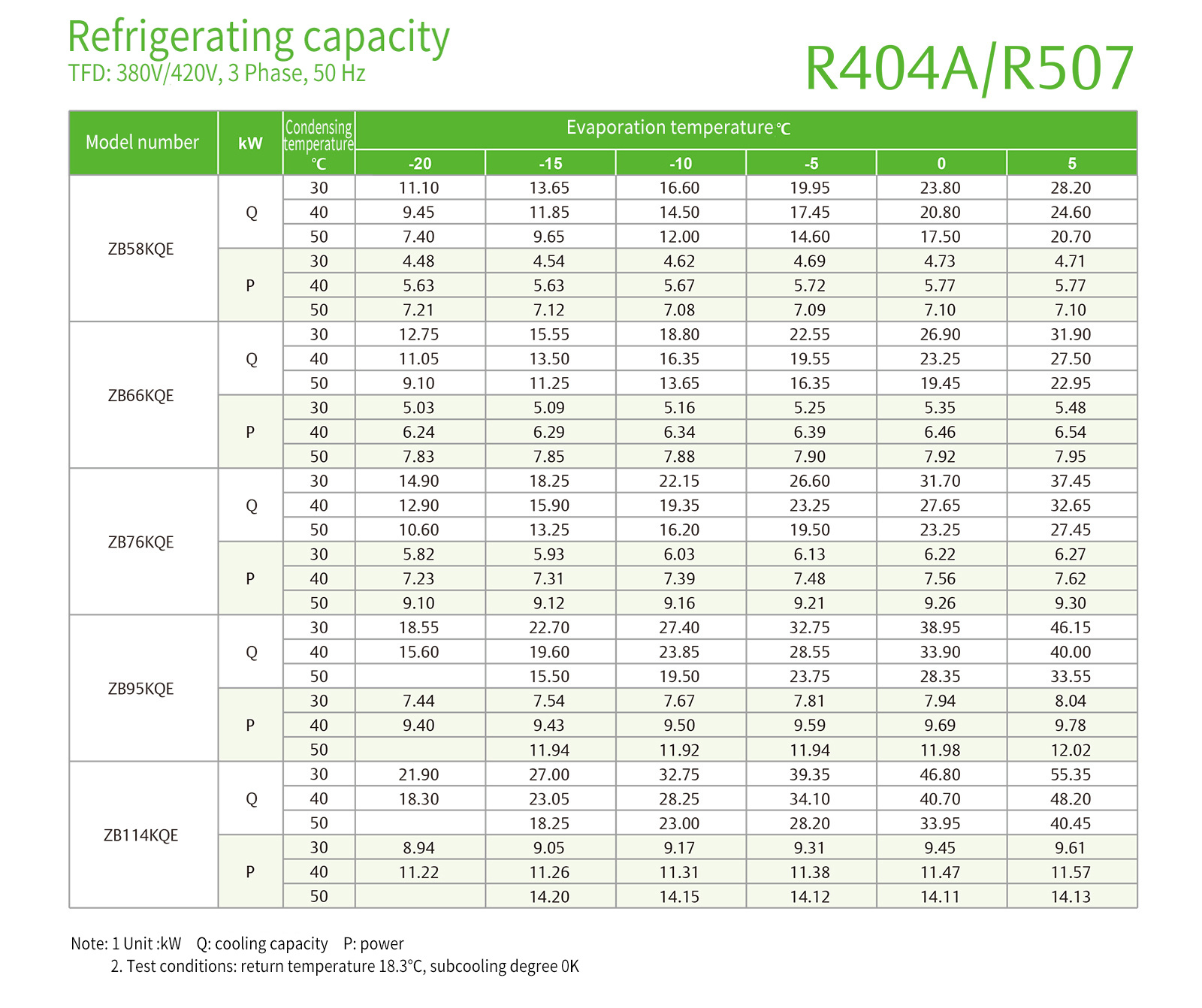

Cooling capacity data

Compressor refrigerating capacity data listed in this sample, no liquid supercooling degree, power frequency 50Hz (motor synchronous speed 2900rpm). When the compressor is operated at a frequency of 60Hz (motor speed 3500rpm), the cooling capacity and the input power increase by about 20%. The compressor should not be used outside the scope of application.

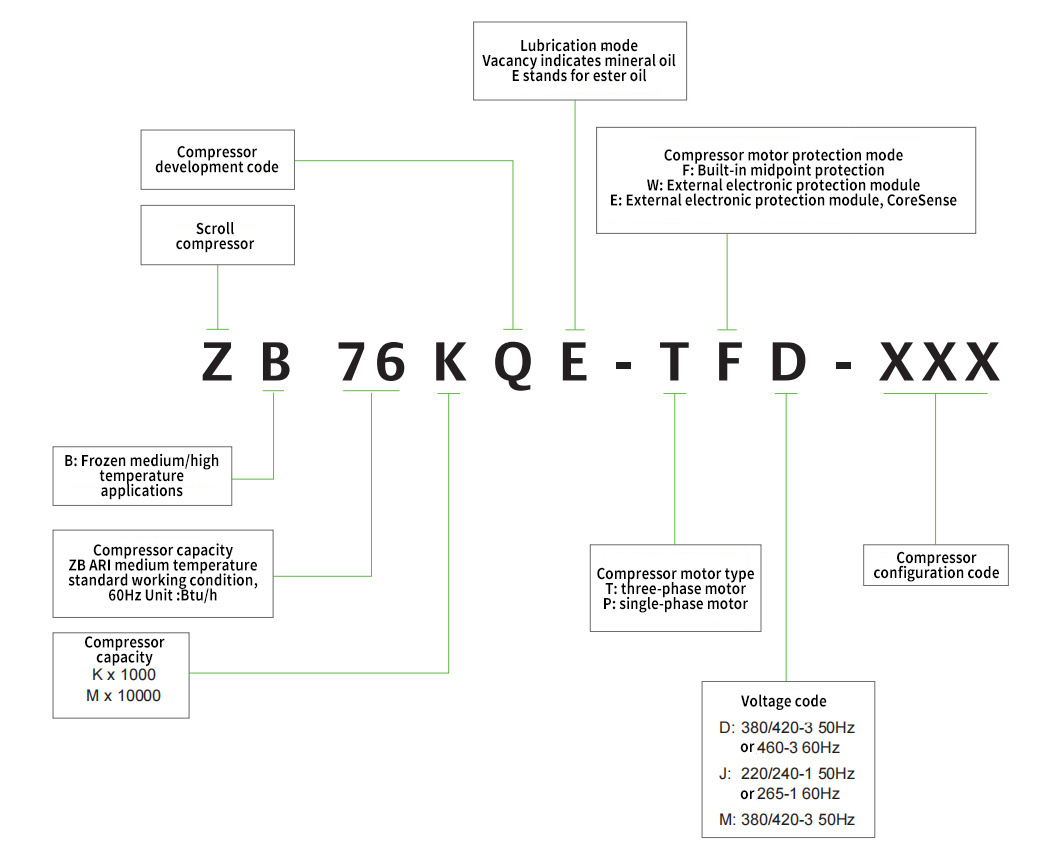

Naming Rules

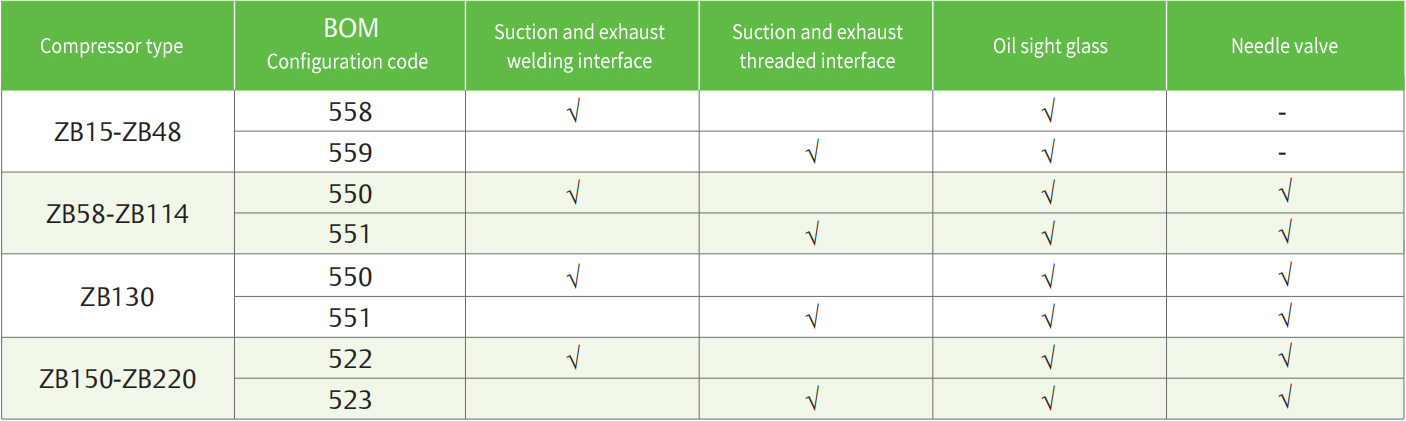

Compressor Configuration Description

recommend products

Get free product quotes

Mobile website

More wonderful waiting for you!

Address: No. 330-3, Dingxiang Street, Sujiatun District, Shenyang City, Liaoning Province

Mobile:15841552555(WeChat synchronization)

E-mail:northsnow_trade@outlook.com