ZSI Copeland®(Copeland) integrated condensing unit

Key words:

Classification:

Product Description

BCZSI type low temperature refrigeration type condensing unit

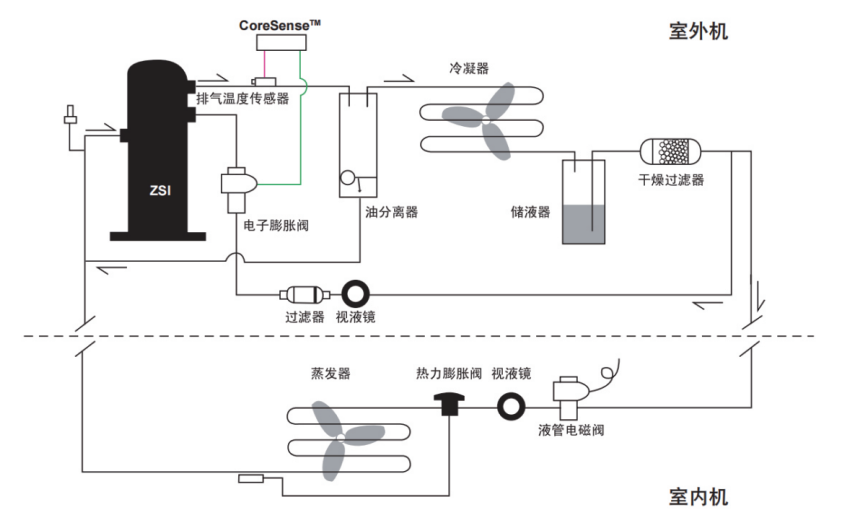

ZSI and CoreSense™Diagnostic Module

ZSI Scroll Compressor Product Information

Motor horsepower: 2-7.5 HP

Operating range: medium temperature and low temperature operation

Refrigerant:

R22,R404A

The main advantages of ZSI scroll compressors

Scroll compressors for higher energy efficiency and reliability

☆ Compared with piston compressors, scroll has a higher energy efficiency ratio, and each scroll compressor saves 10%-30% of electric energy or 600-3000RMB electricity cost per year based on different models.

☆ Reduced moving parts compared to traditional piston compressors, resulting in higher reliability

☆ Patented two-way flexible design, which can separate the scroll along the axial and radial directions, and liquid and debris pass through the scroll without damaging the compressor

Scroll compressor runs smoothly

☆ Continuous compression process, smaller vibration, more quiet operation

☆ No complex internal suction and exhaust valve design, quiet operation, more reliable

Wide range operation

☆ Low to medium temperature application, covering -30 ℃ to 0 ℃ evaporation temperature

☆ CoreSense™Control liquid spray technology to improve the reliability of operation under low temperature conditions

☆ Wider operating range reduces inventory requirements

CoreSense™Diagnostic Module

ZSI scroll compressor utilization CoreSense™Diagnostic system for controlling liquid injection by measuring exhaust gas temperature. This technology not only expands the operating range of the compressor, but also ensures its reliability. CoreSense™The control board prompts the user of the sensor status and the operation of the electronic expansion valve through the LED light signal. Through this "smart compressor" strategy, Emerson aims to provide customers with better compressor protection, using exhaust temperature and electronic expansion valve monitoring to reduce the possibility of failure, and bring higher value and benefits to users.

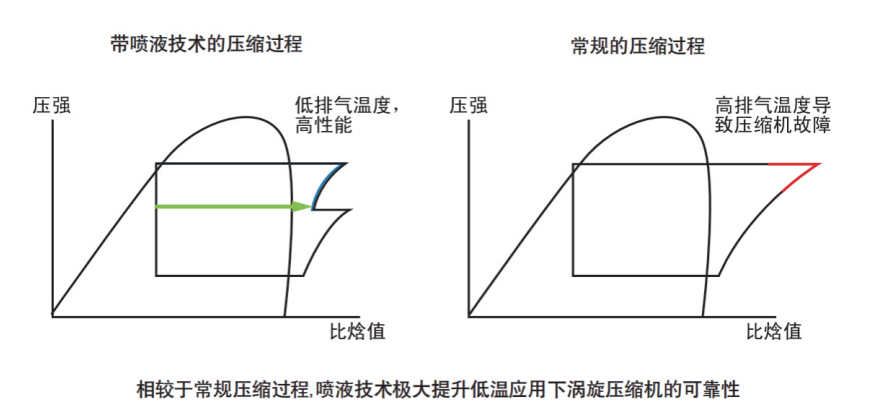

Through the CoreSense™Controlled liquid injection technology avoids compressor failure due to high discharge temperature

☆ Precise control of the amount of liquid sprayed by monitoring the temperature of the exhaust pipe

☆ LED lights display exhaust pipe temperature sensor and electronic expansion valve] operating status to help customers determine the cause of the fault more quickly and accurately

Liquid spray technology to ensure the exhaust temperature

The ZSI scroll compressor must use the standard electronic expansion valve during liquid injection operation. The valve can be matched to all refrigerants compatible with ZSI compressors.

Liquid spray technology for efficient operation

System configuration diagram

When the ZSI compressor is applied, a liquid spraying circuit is required to connect the liquid pipe and the liquid spraying device of the compressor. A liquid sight mirror can be installed in front of the electronic expansion valve of the liquid spraying circuit to monitor the liquid extraction status.

Please note that ensuring that the spray circuit can provide sufficient liquid is the key to achieve this function.

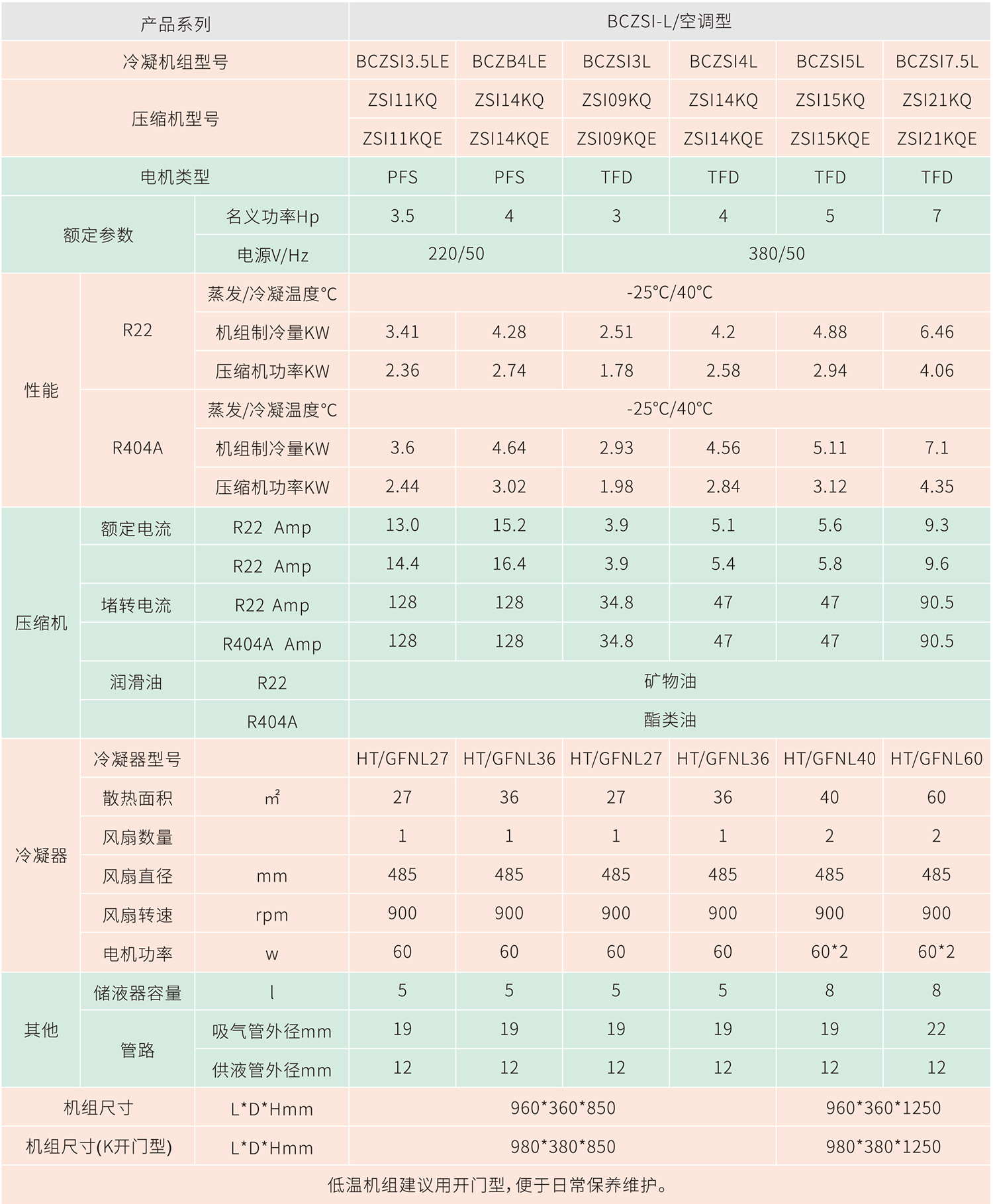

BCZSI low temperature refrigeration series performance parameters

recommend products

Get free product quotes